The Best Strategy To Use For Roar Solutions

The Best Strategy To Use For Roar Solutions

Blog Article

Unknown Facts About Roar Solutions

Table of ContentsAbout Roar SolutionsAbout Roar SolutionsThe Single Strategy To Use For Roar SolutionsIndicators on Roar Solutions You Need To Know

The equipment register is a detailed data source of devices documents that consists of a minimum set of areas to determine each item's place, technological specifications, Ex-spouse classification, age, and ecological data. This details is essential for monitoring and taking care of the tools effectively within unsafe locations. In comparison, for routine or RBI tasting examinations, the grade will be a combination of Comprehensive and Close evaluations. The ratio of Comprehensive to Close examinations will certainly be identified by the Equipment Danger, which is examined based upon ignition danger (the probability of a resource of ignition versus the likelihood of a combustible environment )and the hazardous location classification( Zone 0, 1, or 2). This variation will likewise influence the resourcing requirements for job preparation. Once Lots are specified, you can establish sampling strategies based on the sample size of each Great deal, which describes the number of random equipment things to be inspected. To figure out the required example size, two elements need to be reviewed: the dimension of the Lot and the classification of inspection, which shows the level of effort that must be used( lowered, normal, or increased )to the assessment of the Lot. By integrating the category of inspection with the Lot size, you can then establish the ideal being rejected standards for a sample, suggesting the allowed number of malfunctioning products located within that example. For more information on this procedure, please refer to the Power Institute Standards. The IEC 60079 conventional advises that the maximum interval in between examinations need to not exceed 3 years. EEHA assessments will certainly also be performed beyond RBI projects as part of set up maintenance and equipment overhauls or fixings. These evaluations can be attributed toward the RBI sample sizes within the influenced Lots. EEHA evaluations are carried out to determine mistakes in electrical tools. A weighted scoring system is vital, as a single piece of tools may have numerous faults, each with differing degrees of ignition risk. If the mixed score of both examinations is less than twice the mistake rating, the Lot is considered appropriate. If the Great deal is still thought about unacceptable, it must undertake a full examination or validation, which might set off stricter assessment protocols. Accepted Lot: The root causes of any faults are recognized. If a common failure mode is discovered, added equipment may need examination and fixing. Mistakes are identified by intensity( Security, Integrity, Home cleaning ), making certain that urgent problems are evaluated and resolved quickly to mitigate any type of effect on safety or procedures. The EEHA data source should track and record the lifecycle of faults together with the corrective actions taken. Executing a durable Risk-Based Assessment( RBI )technique is essential for guaranteeing compliance and safety and security in handling Electric Equipment in Hazardous Locations( EEHA). Automated Mistake Scoring and Lifecycle Monitoring: Effortlessly take care of mistakes and track their lifecycle to enhance assessment accuracy. The intro of this assistance for risk-based inspection better reinforces Inspectivity's position as a best-in-class option for governing conformity, as well as for any type of asset-centric evaluation usage situation. If you have an interest in finding out more, we invite you to ask for a presentation and uncover exactly how our remedy can change your EEHA administration processes.

With over 10 years of combined Ex-spouse experience (IECEx/ATEX, EEHA), Saipex started to advertise the value of capability of all employees associated with the Hazardous Area field in 2019. In 2021, our partnership with IndEx and Technology Ability International (TSI) marked a milestone in the Saipex roadway to continue Ex lover renovation.

The 30-Second Trick For Roar Solutions

In terms of explosive danger, a hazardous location is an environment in which an explosive environment is existing (or might be expected to be existing) in amounts that call for unique precautions for the construction, installation and usage of devices. In this post we discover the difficulties dealt with in the workplace, the danger control measures, and the called for competencies to function safely.

(http://peterjackson.mee.nu/do_you_ever_have_a_dream#c2270)

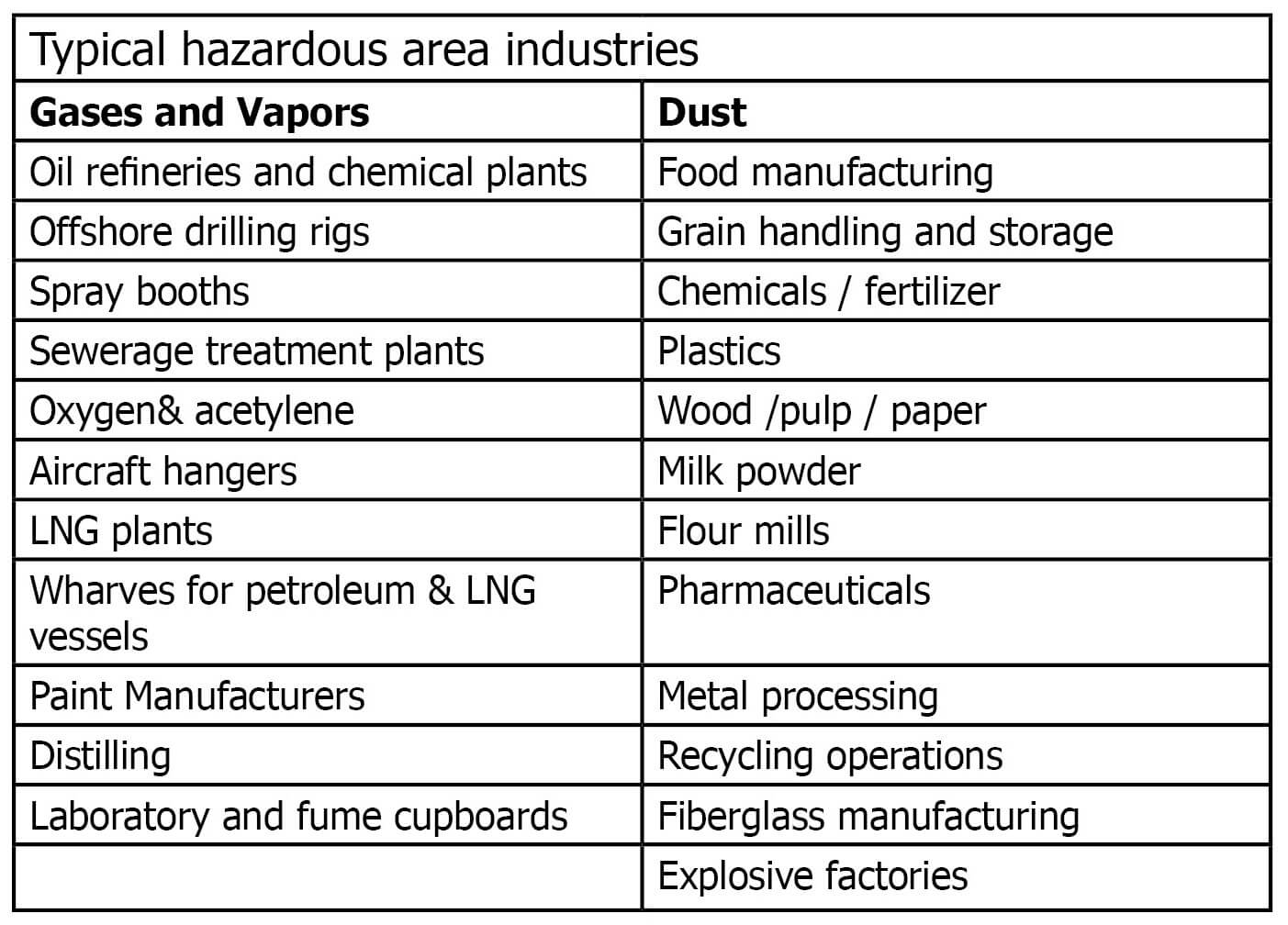

It is a repercussion of modern-day life that we make, keep or handle an array of gases or fluids that are considered combustible, and an array of dusts that are regarded combustible. hazardous area electrical course. These compounds can, in certain conditions, create explosive ambiences and these can have significant and heartbreaking consequences. Many of us know with the fire triangle remove any one of the three aspects and the fire can not occur, however what does this mean in the context of unsafe areas? When breaking this down right into its simplest terms it is essentially: a combination of a specific amount of launch or leak of a specific material or product, blending with ambient oxygen, and the presence of a source of ignition.

This is after that verified through examination and testing and is preserved throughout the life of the installment by utilizing the correct upkeep methods, supplemented by periodic examination. When all these steps are taken, they ought to likewise be documented. The confirmation dossier includes info such as the harmful area category drawing, makers' paperwork, tools qualification, design illustrations and estimations, evaluation records, and records of an individual's expertise and continuing specialist advancement (CPD), such as using ECA's eCOMS software.

Our Roar Solutions Ideas

It is essential that pupils recognize and have a complete knowledge regarding just what makes up a harmful location. The trainee needs to additionally recognize why training is essential prior to trying to handle work or defining devices into a harmful location. These locations are additionally called categorized locations and are specified as locations which have a high probability of an explosion because of the possible existence of combustible gases, vapors, cleans and so on.

Industries that consist of harmful locations are currently demanding that electric workers that are specifying or operating in these areas need to have a dangerous location certification that considers them competent. Jobs in these sectors are really satisfying so you need to be prepared. To fulfill this need for the market, nationally identified training in Certification IV in Hazardous area Electric and EEHA training on the growth of experienced professionals.

The Roar Solutions Diaries

Tech Skills Australia is a Registered Training Organization providing you with the most budget friendly and quickest means in obtaining your credentials - hazardous area electrical course. Our trainers are industry certified and have numerous years of process experience. Our programs have assisted hundreds of people from business supervisors to day-to-day employees in acquiring a solid hold on this not so difficult however high risk training

The training additionally includes determining the dangerous locations, resources of surge and the buildings of harmful products together with the duties and functions of all celebrations, regulations, systems, requirements and practice codes attached to unsafe areas. We give instrumentation and hazardous location remedies that are in conformity to newest AS/NZS and international sector requirements.

Report this page